WE CHAT

139-9869-7660

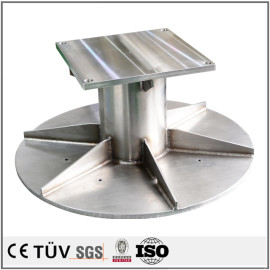

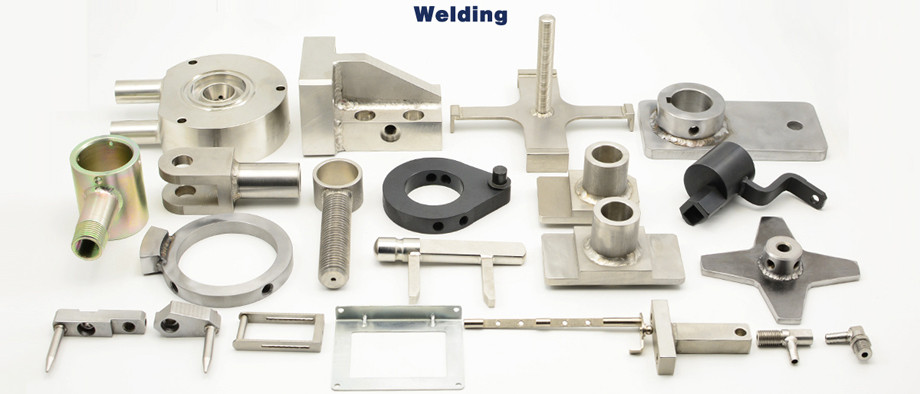

Welding parts

| Welding equipment: | Equipment category Specific application scope |

| Argon welder | Widely used in large, medium and small parts, sheet metal chassis, sheet metal class welding.Small deformation, beautiful welding. |

| Carbon dioxide gas shielded welding machine | Widely used in large, medium and small parts welding, greatly improve the welding efficiency |

| Cold welding machine | Used for the repair of the out-of-tolerance of precision and small parts |

| Laser welding machine | Used for precision welding of micro and small parts |

| Resistance welding machine | Used for sheet metal chassis, sheet metal parts spot welding processing |

| Welding quality inspection: | Welding meat defects Specific description |

| Spurious welding | Spurious welding refers to the welding defects such as unfused and disconnected welds (the weld length required by the process cannot be guaranteed). |

| Air breather | Piercing hole on the surfaces of welding spot |

| Crack | Cracks appears in the weld. |

| Slag inclusion | solid entrainment. |

| Undercut | The excess between the weld and the base material is too severe |

| Burning through | The base material was burnt through. |

| Splashing | Metal liquid fly out and stick to the area of functional and appearance requirements. |

| Over high weld is convex | The weld is too big,H values does not allow more than 3mm. |

| Position deviated | Weld position is not correct. |

| Coordinate with bad | plate butt joint gap is too big. |

Engineering factor:

1.Welding material shall conform to design requires and provisions of relative standards, the certificate of quality and other relevant information shall be checked.

2.Welder shall pass the examination, to check the welder's corresponding welding conditions and the date of assessment.

3.Class I II welds shall be tested for flaw detection and conform to design requires, construction and acceptance specifications. Providing reports of flaw detection on welds.

4.Uniform appearance of the weld seam, smooth transition between welds and welding toe, Cleaning up the welding spatter.

5.I, II class welds shall not exist the defective situation of incompletely filled weld, undercuts, non-shrinkage, and crack, blowholes and arc strike on the surface.

2.Welder shall pass the examination, to check the welder's corresponding welding conditions and the date of assessment.

3.Class I II welds shall be tested for flaw detection and conform to design requires, construction and acceptance specifications. Providing reports of flaw detection on welds.

4.Uniform appearance of the weld seam, smooth transition between welds and welding toe, Cleaning up the welding spatter.

5.I, II class welds shall not exist the defective situation of incompletely filled weld, undercuts, non-shrinkage, and crack, blowholes and arc strike on the surface.

301 products found

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

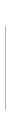

Customized MIG welding service CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

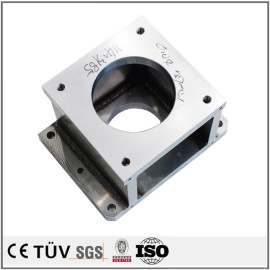

customzied stud welding CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

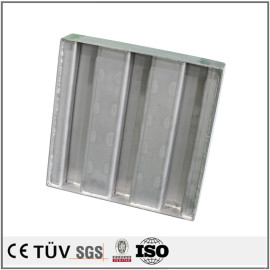

customized MIG welding service CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized argon welding CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized MIG welding fabrication CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized electric welding CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized protable welding CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized precision welding CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

high quality customized welding CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized welding processing CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized welding processing CNC machining for car parts

dalian hongsheng provide high quality spot welding technology processing CNC machining for car parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized welding CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized welding CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized welding equipment processing CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized pressure welding processing CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized electroslag welding technology processing CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

Customized electroslag welding processing CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

Customized plasma welding processing CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

Customized gas welding technology processing CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

Customized electric-arc welding technology processing CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

Customized electric-arc welding processing CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

Customized fusion welding technology processing CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized sheet metal fabrication bending welding CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized welding stainless steel processing CNC machining parts

Outstanding customized stamping bending welding processing CNC machining for ice-cream machine parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized stamping bending welding processing CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

Customized welding fabrication CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized sheet metal forming stamping welding CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized stamped and welding CNC machining parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized Forming Bending Welding parts

Classic customized sheet metal welding fabrication CNC machining therapeutic apparatus machine parts

MOQ: 1 piece

Unit Price: US $ 1.5 / piece

customized sheet metal welding fabrication parts

write to us

Please send your message to us

- Tel

- *Title

- *Content

MOBILE WEB

Contact us

Hongsheng provides customers with high quality, professional machining services, welcome to contact us at any time!

subscription

Contact Person

- Tel:

86-411-87516616-828

- Email:

- hongsheng@dlhshjx.cn

- Address:

- 19-2, Liaoning Street, Jinpu New District, Dalian City, Liaoning Province, China.