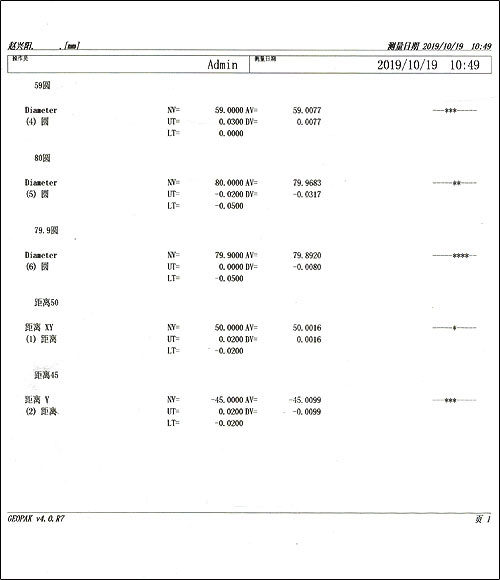

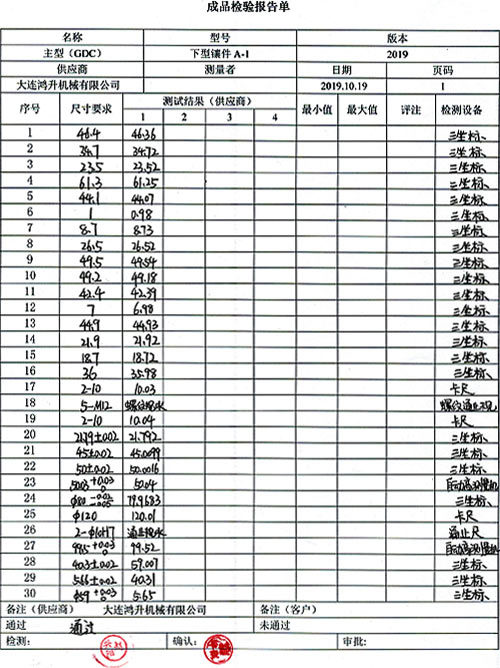

Home / Quality Inspection Report Display

write to us

Please send your message to us

- Tel

- *Title

- *Content

MOBILE WEB

Contact us

Hongsheng provides customers with high quality, professional machining services, welcome to contact us at any time!

subscription

Contact Person

- Tel:

86-411-87516616-828

- Email:

- hongsheng@dlhshjx.cn

- Address:

- 19-2, Liaoning Street, Jinpu New District, Dalian City, Liaoning Province, China.