High precision CNC machining center stainless steel mold parts fishing gear mold core

High precision CNC machining center stainless steel mold parts fishing gear mold core

| Categories | Other mould |

|---|---|

| Brand | HSH Machine Parts Processing Manufacturer |

| Model | fishing gear mold core |

| Location | Dalian,China |

| Product Name | A7075 Aluminum Mould |

| Application | fishing industry |

| Material | A7075 |

| Tolerance | up to 0.01mm |

| Certification | ISO9001:2008 |

| Service | OEM service |

| QC | 100% inspection on critical dimension |

| Unit Price | US $ 1.5-5 / piece |

| FOB port | Dalian |

| Terms of Payment | Western Union, T/T, Paypal |

| Update Time | Feb 4,2025 |

| Item Name | High precision CNC machining center stainless steel mold parts fishing gear mold core | |||||

| Quality Assurance | ISO9001:2008 Certified | |||||

| Main Equipment | The capacity of equipment involve DMG 5-axis Machining centers, Mazak 5-axis machine,YASDA YBM-8120V,DMG CNC universal turning machines, 4-axis and 3-axis Machining centers, Sodick wire cutting machine, Mitutoyo CMM and etc. More than 40 high grade machining and testing equipment of all kinds. | |||||

| Materials | Aluminum Alloy: | |||||

| 5052 /6061/ 6063 / 2017 / 7075 / etc. | ||||||

| Brass Alloy: | ||||||

| 3602 / 2604 / H59 / H62 / etc. | ||||||

| Stainless Steel Alloy: | ||||||

| 303 / 304 / 316 / 412 / etc. | ||||||

| Steel Alloy: | ||||||

| Carbon Steel / Die Steel / Spring Steel etc. | ||||||

| Other Special Materials: | ||||||

| Lucite / Nylon / Bakelite / POM / ABS / PP / PC / PE / PEEK / Titanium etc. | ||||||

| We handle many other type of materials. Please contact us if your required material is not listed above. | ||||||

| Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting | |||||

| Inspection | Mitutoyo three-coordinate measuring machine / Mitutoyo tool microscope/digimatic micrometer/inside micrometer/go-no go gauge/dialgage/ electronic digital display caliper/automatic height gauge/ precision level 2 detector/precision block gauge/00 levels of marble platform/ring gauge | |||||

| File Formats | The production drawings can be sent in CAD, DXF, STEP, IGES, x_t and other formats, supporting the use of CAD, Soildwork UG ProE and other softwares. | |||||

| Application | 80% of the objects in production and lifeare made bymold processing, mold is the mother of industry. The products produced by the mold are widely used in the home appliance industry: ricecookers, washing machines, air conditioners, refrigerators and other decorative panels; automotive industry: instrument panels, air conditioning panels, lamp housings, sign lights; electronics industry: computers, DVD, Cameraand other decorative shells; computer industry: keyboard, mouse shell;communications industry: mobile phone buttons, housing, window lenses; other industries:cosmetics boxes, gift boxes, decorative boxes, toy | |||||

| Customer distribution | Thank you for your attention. Our clients are mainly in Japan, Germany, USA, UK, Canada, Sweden and FinlandLAN, Belgium, Australia, Russia, India, Turkey, Austria, Netherlands, Portugal, Spain, Switzerland,Denmark, Norway, New Zealand, Malaysia, Egypt, Peru, Mexico, Singapore, Saudi Arabia, Mauritius,Peru, Zambia, el Salvador, Israel and more than 40 countries and regions). Japan accounts for 70 percent of the market, Europe and the United States account for15%, others 15% | |||||

| The use of Tool Microscope Making smaller, customized service workpieces, dimensional measurements are usually made on a 2D plane. For example, measuring the aperture and hole spacing with the size of around φ1mm, the position where the gauge can not touched, and the relatively weak measurement contact surface. The product local details can be enlarged by using the tool microscope for an accurate measurements. |

The use of CMM Multi-Joint Arm Measurements are made for workpieces that are inconvenient to move, or for workpieces that are not being reassembled on the equipment. When there is a similar product, the measuring arm can be moved and used as long as it is fixed on a stable surface and calibrated. The function is similar to the three-coordinate detector, but it is more flexible. |  |

| The use of high precision automatic measuring machine Common tools for inspection and final inspection, easy to operate.Taking the marble platform as the benchmark,It is usually used to measure the height of the workpiece, the overall dimensions, the dimensions between the surface and the surface, and the dimensions between the center and the surface.The precision is about 0.005-0.01mm. |

Rockwell hardness tester Hardness testing is an important part of product testing. According to the customer's processing requirements, if the product need to heat treatment.We will arrange the heat treatment outsourcing factory for processing.The products after heat treatment should be sent to the quality inspection room for hardness test.The next step of the process can not be carried out until the product is qualified. (in the figure, the quality inspector is testing the hardness.) |  |

| The use of Ordinary Measuring Implement The most common test method at work. The measuring tool includes a micrometer, an inner diameter micrometer, a digital caliper, a depth gauge, a through stop gauge, a feeler gauge, a gauge block, and the like. After the test personnel get the product to be inspected, they will conduct a full inspection according to the requirements of the drawings. After the test is passed, they will be covered with their own name. Finally, the inspection drawings with the name of the inspector will be delivered to the customer with the product in order to trace the quality of the product. |

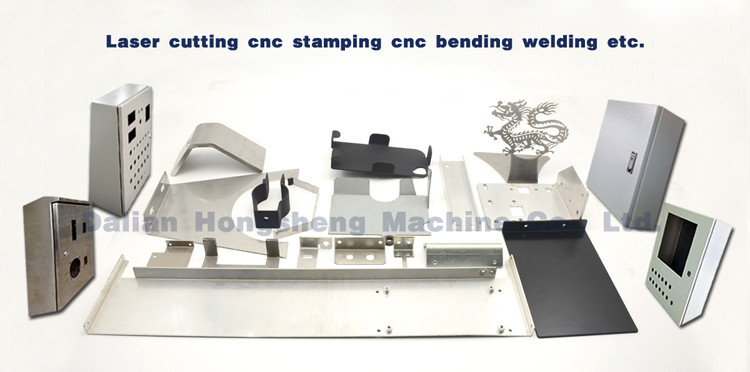

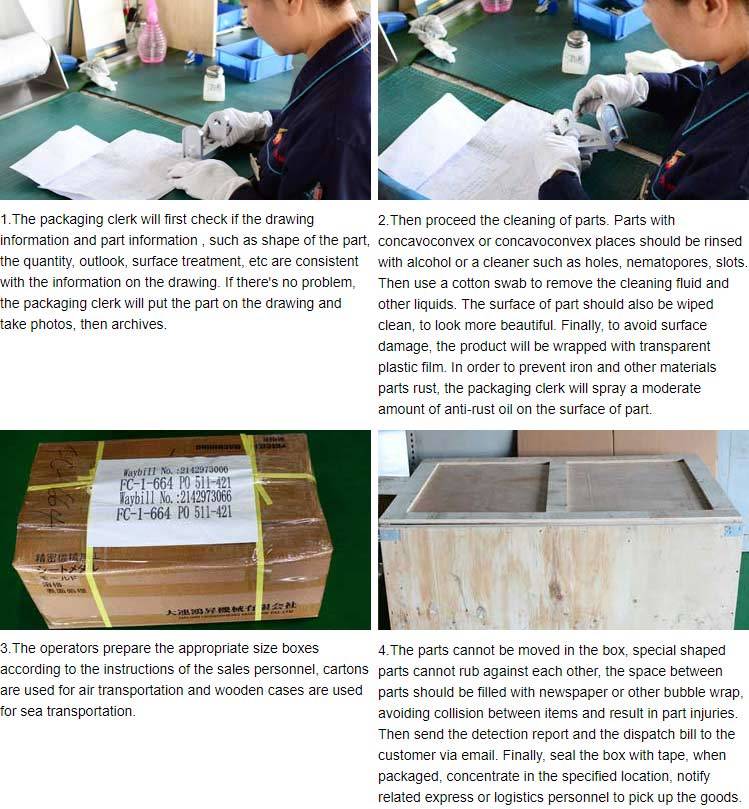

1,warp them in packaging foam

2,To be packed in cartons.

3,Use glues tape to seal cartons.

4,DHL/UPS/FEDEX/TNT/OCS are shipped by default. If the customer has demand,

We can also choose express delivery according to customers' requirements

This is mainly for small pieces (within 300kg).

For large parts, we will use air or sea transportation according to customers' requirements.

Generally, it takes 4-5 days to ship to Japan by air and 7-10 days to ship by sea.

It takes 7-10 days to ship the goods by air in Europe and America,

and 15-20 days to ship the goods by sea.

A: Please send us an email, we will contact you as soon as we receive your email.

Q: How long can we get samples in a general way ?

A: It depends on your project, usually 10-20 days can deliver.

Q: How to enjoy OEM service?

A: Generally speaking, we refer to your drawings or original samples, offer some techniques, suggestions and quotations to you. We will produce for you after you agree. we produce the drawing with your approval.

Q: What's kinds of information you need for quote?

A: The production drawings can be sent in CAD, DXF, STEP, IGES, x_t and other formats, supporting the use of CAD, Soildwork UG ProE and other softwares.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content

Hongsheng provides customers with high quality, professional machining services, welcome to contact us at any time!

- Tel:

86-411-87516616-828

- Email:

- hongsheng@dlhshjx.cn

- Address:

- 19-2, Liaoning Street, Jinpu New District, Dalian City, Liaoning Province, China.