China manufacturer custom made precision sheet metal stamping forming construction fittings parts

China manufacturer custom made precision sheet metal stamping forming construction fittings parts

| Categories | Sheet metal parts |

|---|---|

| Brand | HSH Machine Parts Processing Manufacturer |

| Model | sheet metal parts |

| Name | sheet metal parts |

| Surface treatment | Blacking,polishing,anodize,chrome plating,etc |

| Process | Bending, welding, assembling, etc |

| Service | OEM/ODM/Customized |

| Tolerance | 0.010~0.002mm,or other customer's requirement |

| Application | Used Widely Industry Auto |

| Certificate | ISO9001:2008 |

| Finish | Customer's requirement |

| Material | metal |

| OEM service | be preferred |

| Unit Price | US $ 0.5 / piece |

| FOB port | Dalian Port |

| Terms of Payment | Western Union, T/T, Paypal |

| Update Time | Jan 23,2025 |

Dalian Hongsheng Machine Co., Ltd

We specialized in Welding, Machining, Casting and SheetMetal for 15 years. Our excellence in the welding field allows us to provide our services to a large variety of businesses in a safe, professional manner.

Production Description

| Item name | China manufacturer custom made precision sheet metal stamping forming construction fittings parts |

| Material | Aluminum Alloy: |

| 1060/3003/5052/6061/6063 | |

| Brass Alloy: | |

| 3602 / 2604 / H59 / H62 /H68 etc. | |

| Stainless Steel Alloy: | |

| SS201/SS202/SS303/SS304/SS613 etc. | |

| Steel Alloy: | |

| Q235/Q345/A1008/A1010/A1045 etc. | |

| Please contact us if your required material is not listed above. | |

| Thickness | As per your requirements |

| Tolerance | As per your requirements |

| Surface Treatment | ganlvanized, power coating, anodizing, polishing, passivation, sand blasted,chrome plating,zinc plating,nick plating,mirror polishing etc. |

| MOQ | Accept order for small bathces |

| Size | Client's drawing |

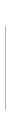

| Processing | Our process includes cutting, profiling, tooling fabrication, stamping, deep drawing, punching, spinning, laser cutting, bending, seamless welding, machining and assembly |

| Equipment | CNC shearing machine, mechanical press 5 t - 400 t, 315 t hydraulic press, surface grinding machine, 160 t press machine, 80 t pressing machine, welding machine, rolling machine, plasma cutting machine, CNC steel cutting machine, CNC bending machine, bending machine, shearing machine, submerged arc welding, gas shielded arc welding, argon arc welding, large spray booth, large CNC vertical lathe, large sleeping lathe, large milling machine, surface grinding large boring and milling machine, large CNC, large CNC boring and milling machine, large drilling machine, etc. and more euipments |

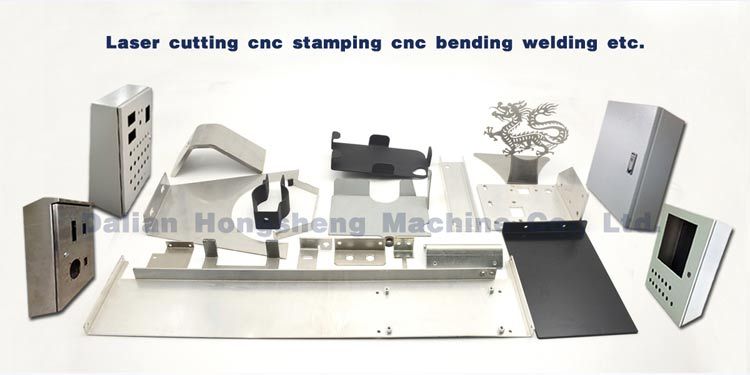

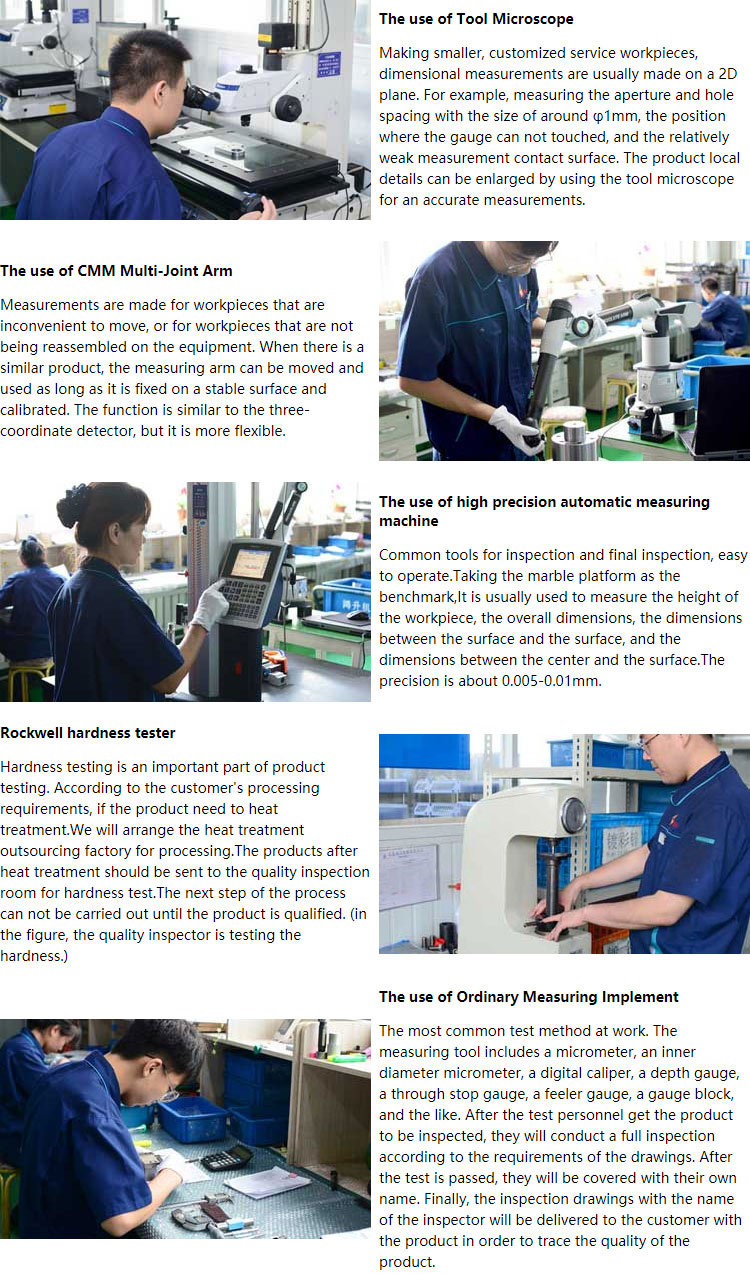

| Testing equipment | Severals advanced inspection equipments imported from Japan, such as Mitutoyo Coordinate measuring machine, Tool microscope, multi-joint arm, Automatic height gauge, Manual height gauge, Micrometer, Dial gauge; Marble platform; Roughness measurement, etc. Inspecting equipment for welding parts: Platform, roughness measurement, flaw detection, radiographic inspection, callipers, meter ruller, welded junction stength test, etc.and more testing equiptment |

| Inspection | Dimension check, External environment inspection, appearance inspection, incoming quality control, finished product inspection, flaw inspection |

| Lead time | 20-40 working days, according to customers'requirements and quantity of products |

| Drawing Formates | Solid Works, AutoCAD(DXF,DWG),PDF,TIF,IGS,STP etc. |

| Main Market | Japan/Sweden/USA/Germany/Canada/Italy/United Kingdom/Australia/Pakistan/French , etc |

| Product selling points | 1.Adopting European standard welding, with smooth weld seam, uniform width and depth, penetration depth is deeper than general gas shielded welding and good welding quality. |

| 2.All the materials used CNC cutting machine to ensure the accuracy of blanking. | |

| 3.Using CNC bending machine to ensure product parallelism and verticality after bending. | |

4.Adopting European standard epoxy zinc-rich, with strong adhesion and anti-rust. |

Our Team

Equipment Show

Notice: Except for equipment above, please click for more processing equipment >>

Notice: Except for equipment above, please click for more testing equipment >>

Products Show

Other Business Items

Machining

SheetMetal

Casting

Quality Control

Please click for more testing equipment >>

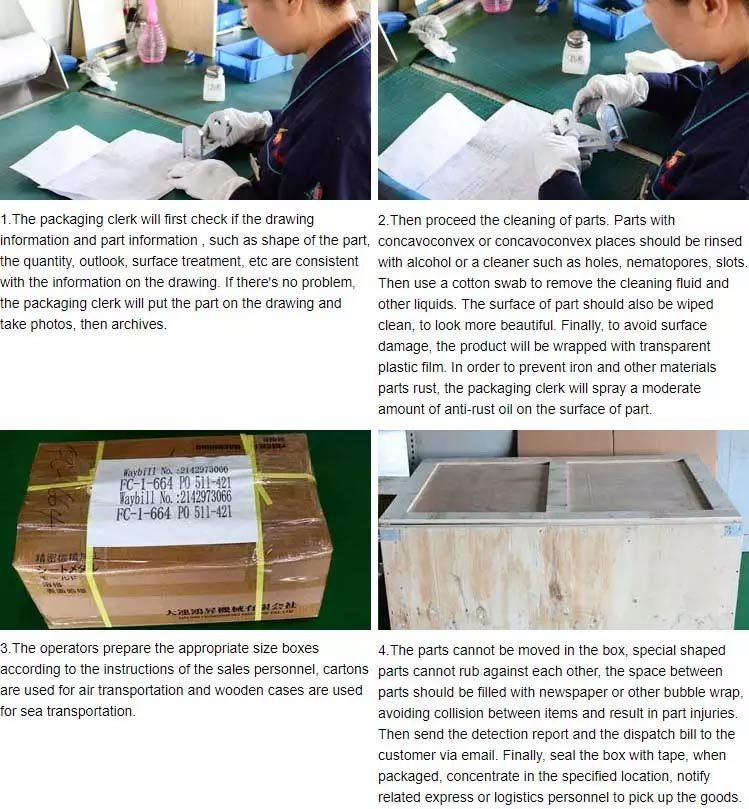

Packing & Delivery

Customer Photo

FAQ

Q: Where can I get the product information and price information?

A: Please send us an email, we will contact you as soon as we receive your email.

Q: How long can we get samples in a general way ?

A: It depends on your project, usually 10-20 days can deliver.

Q: How to enjoy OEM service?

A: Generally speaking, we refer to your drawings or original samples, offer some techniques, suggestions and quotations to you. We will produce for you after you agree. we produce the drawing with your approval.

Q: What's kinds of information you need for quote?

A: The production drawings can be sent in CAD, DXF, STEP, IGES, x_t and other formats, supporting the use of CAD, Soildwork UG ProE and other softwares.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content

Hongsheng provides customers with high quality, professional machining services, welcome to contact us at any time!

- Tel:

86-411-87516616-828

- Email:

- hongsheng@dlhshjx.cn

- Address:

- 19-2, Liaoning Street, Jinpu New District, Dalian City, Liaoning Province, China.